Control System Concepts / Scope of Work

We know it is extremely important to get a control system project off on the right foot by insuring all parties have a good understanding of the work that is to be done. That is why we ask for or we produce, in writing a Scope Of Work and circulate it to get everyone’s input.

Engineering

We take the approved Scope of Work and apply standards and codes, including the SAFETY for the Operators. Next we add the desires for capacity of all areas for SPARES for future expansion and then we apply the Japanese term, POKA YOKE which means to “avoid mistakes“ and anticipate operator confusion or human errors. In English we look for ”Murphy’s Law “ and relook at the design to add steps to alert the operators and avoid these problems.

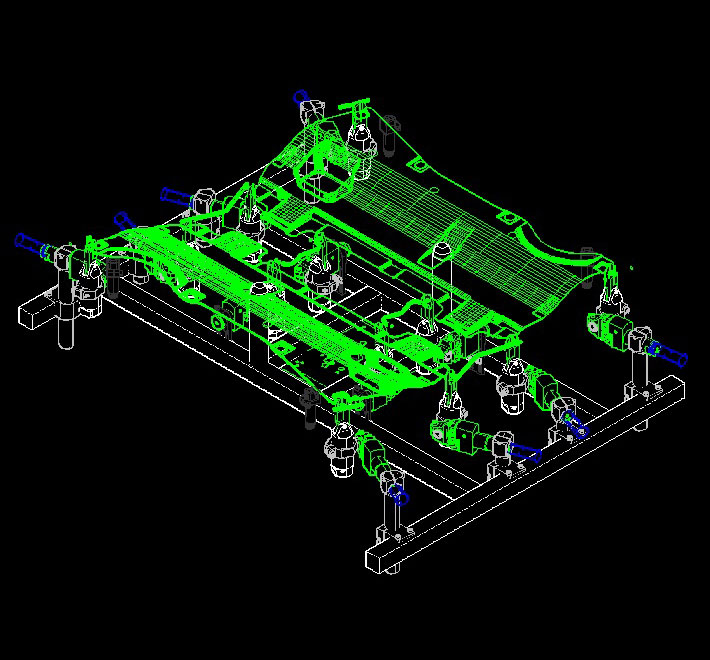

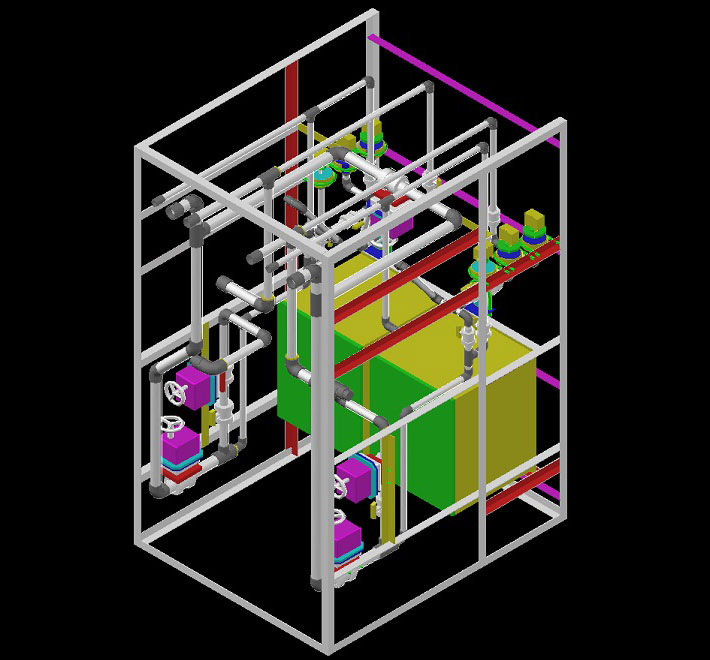

Computer Assisted Design and Drafting (CADD)

Detailed electrical and to scale mechanical drawings are prepared in either AutoDesk, MicroStation, or SolidWorks and submitted for review. Detailed 3D renders help all involved see a more detailed understanding of the work.

PLC System Integration and Programming

Every client has developed their own preference for the control hardware based on the software they have and the training their operators have had. For us to be helpful we must be knowledgeable and have the software for all these different platforms.

In order to "see" how the controls will work a system must have a graphic picture of the process and the logic and we also must know how to produce all of these HMI ‘s ( Human Machine Interface ) displays.

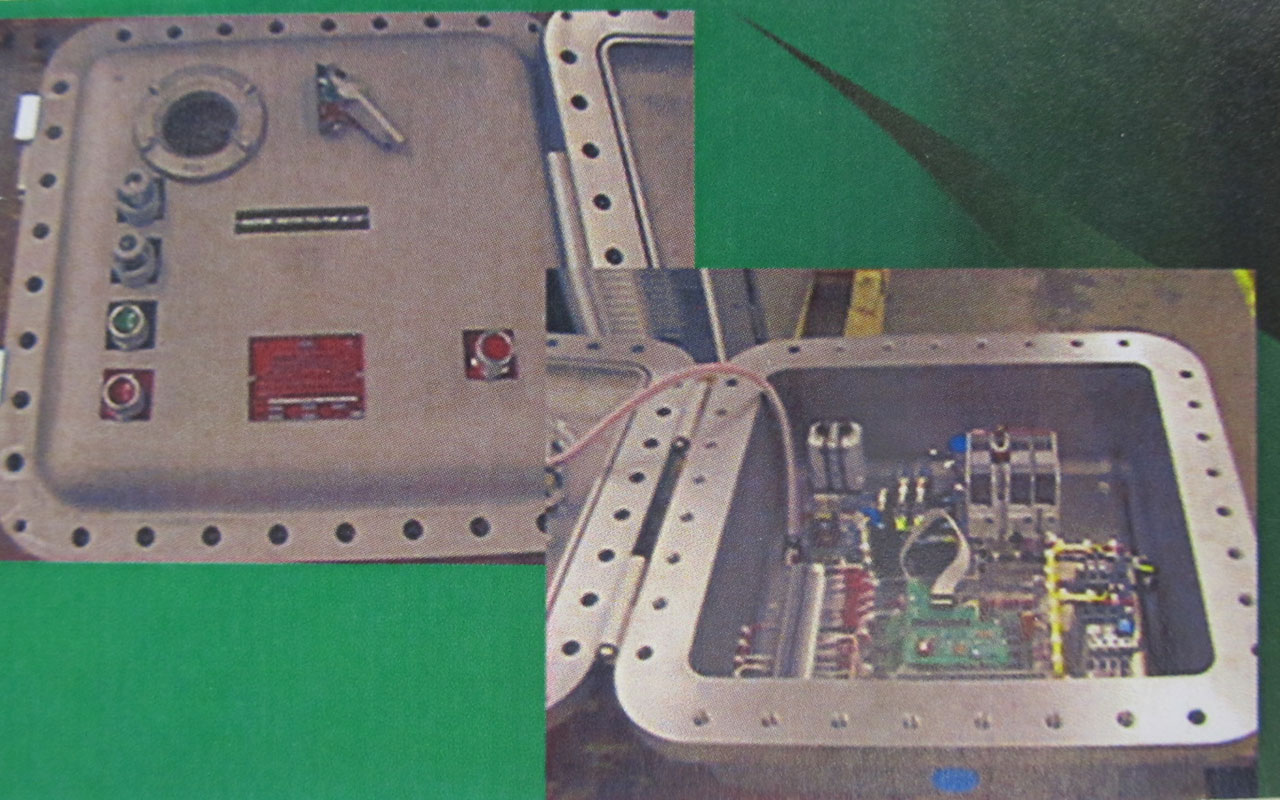

Construction of Control Systems

Not every integrator has the experience and knowledge to make a design, then purchase the correct parts ,build it, and make it work. This is a key BENEFIT OF DTSI. We know building and testing the system will be the ultimate proof design. We also know the client’s personnel must maintain the panel for many years.

Explosion Proof Control Systems

Many projects require that the control panel meet the requirements of Article 500, NEC for operation in hazardous areas. We have years of experience with design of this code.

Site Installation & Testing

Many customers want a SINGLE SOURCE for a system to avoid interface problems. We have provided many of these "Turn Key" projects, some not only involved the panel design, production of over 200 drawings and panel build, but also the installation of over 400 new conduits and thousands of feet of wire. We subcontracted a well known Electrical Contractor to complete our team and the project was done on time and under budget.

Customer Training & Follow Up

We conduct in house training on the details of a control system for the client, and we also go to the site and give hands on, “REAL TIME” training to give all the operators the knowledge they need. ( Many times this training is provided on all the various shifts )

We are very proud of the fact that many clients are so happy with the results of a project that they contract us in the future to help with changes and additions and also to train new personnel.